Air Products will highlight its Freshline food freezing solutions for baking professionals during the International Baking Industry Exposition (IBIE) at the Las Vegas Convention Center in Nevada from September 14-17.

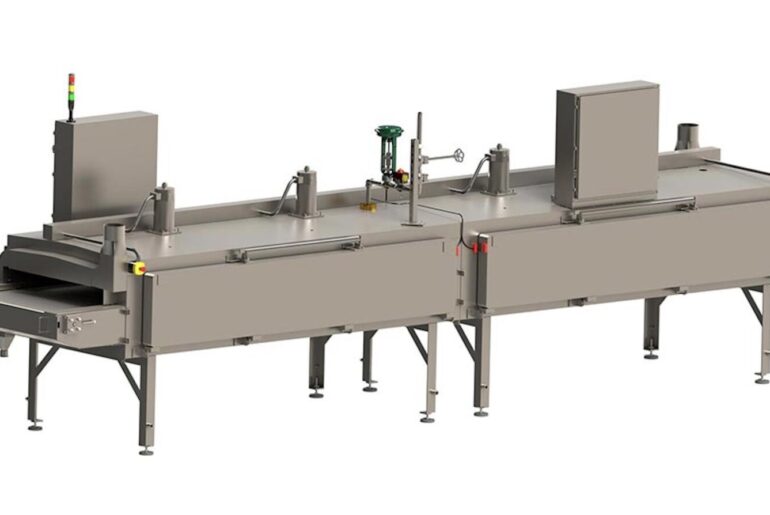

The IQ Freezer is promoted as “the perfect solution for producers looking to chill or freeze a broad range of food products” of various shapes and sizes ranging from pizza and other prepared meals to meat, seafood, poultry and fruits. It is designed in 10-foot modular sections to ensure easy installation and, if additional product throughput is needed, has field expandibility. Integrated hardware also enables processors to use optional remote monitoring software for tracking efficiencies and troubleshooting with remote technicians.

IBIE visitors are invited to visit Air Products’ booth #7656 in the North Hall of the Convention Center to speak with an industry specialist about their specific processes and challenges. Baking professionals will be pitched on the benefits of the company’s Freshline solutions, which use liquid nitrogen (LIN) and carbon dioxide (CO2) to improve a variety of processes, such as food freezing. The extremely cold temperatures of these cryogenic gases enable food products to be chilled or frozen in minutes instead of the hours traditionally required with alternative systems. This rapid freeze results in smaller yield losses and helps to ensure product moisture and quality are preserved.

Held every three years, the IBIE is the largest baking industry event in the Western Hemisphere, bringing together all segments of the grain-based foods industry supply chain. Owned by the American Bakers Association, the Bakery Equipment Manufacturers and Allieds and supported by the Retail Bakers of America, all proceeds from this non-profit event are invested back into the grain-based food industry.

As a leader in cryogenic technology applications for over 60 years, Air Products operates a state-of-the-art food and grinding lab at its headquarters in Allentown, Pennsylvania, USA. Customers and prospects can utilize the facility to test products on production-scale equipment to help determine the feasibility of using cryogenics in their process. Working with industry specialists, prospective customers can quantify the benefits and cost of using cryogenics in their operation without investing in any capital.