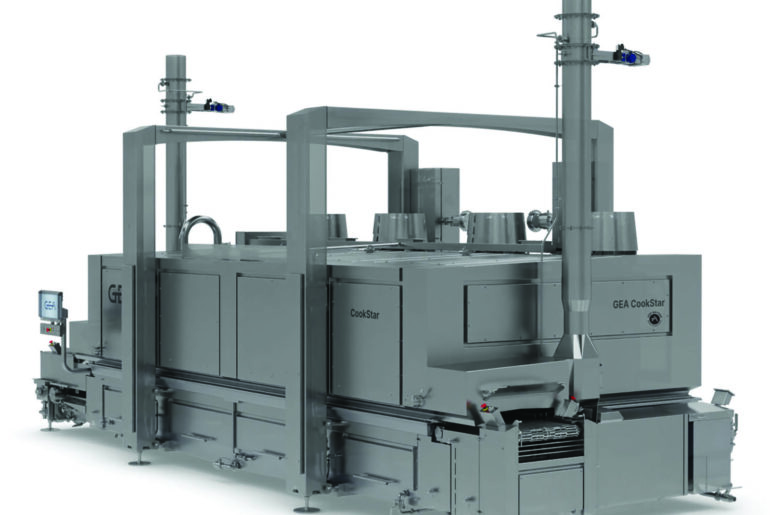

GEA has introduced the CookStar First, a compact twin-zone spiral oven designed for small to mid-sized food production operators seeking to transition from linear to spiral cooking and benefit from the advantages. The line extension addresses requirements for consistent quality, controlled processing conditions and improved resource efficiency from initial start-up. It is designed to create the “home cooked” experience for a broad range of applications, including steam-cooked products, coated poultry, plant-based foods, baked or grilled items and ready meals.

Uniform Heat Distribution and Reduced Cooking Times

The machine features a twin-zone spiral configuration with integrated booster impingement. By combining horizontal and vertical airflow, the system achieves more uniform heat transfer across the conveyor belt. According to Düsseldorf, Germany-headquartered GEA, the core temperature variation across the belt is limited to approximately 1°C, compared with deviations of up to 6°C in conventional ovens. This uniformity enables cooking times to be reduced by 10-30% while maintaining consistent product color and internal doneness. Throughput can reach up to 1,700 kg per hour, and more stable thermal conditions contribute to yield improvements of up to three percent.

Focus on Energy Efficiency

Improving energy efficiency in spiral ovens requires a better oven balance. Company engineers introduced a new intelligent active exhaust system, changes to the oven design, and adjustable product gates to the GEA CookStar First to minimize air leakage. These features work together to ensure consistent cooking conditions throughout the oven. More efficient water flow enables water reuse. Together, these features reduce energy and water consumption by up to 12%.

Process Transparency and Digital Connectivity

CookStar First is equipped with GEA SmartControl HMI, providing operators with access to real-time process data, alarm management, and a 24-hour timeline for tracking events and parameter changes. The system supports consistent operation and data-driven optimization and is compatible with GEA Insight Partner technology for remote diagnostics, service intervention, and maintenance planning.

Compact Footprint and Scalability

With an overall height of less than 3.9 meters, the machine is designed for installation in existing facilities, including brownfield sites with limited ceiling height. The oven’s cooking technology supports a wide variety of products and process parameters.

The broader CookStar family range includes the original CookStar model, which adds smoking functionality and higher capacity, as well as the CookStar Turbo for large-scale applications with capacities of up to 12,000 kg per hour and roasting capability. All systems share a common footprint and can be integrated into existing CookStar production lines.