The new Low Charge Central System (LCCS) from Frick Industrial Refrigeration has been introduced as a reliable, high efficiency central refrigeration system with a total system ammonia charge of approximately 1.5 to 3 pounds per ton of refrigeration. That’s 85% to 95% less than traditional central ammonia systems.

The only centralized system in the super-low charge category (less than 5 lbs/TR) on the market “offers enhanced reliability and efficiency,” said Joseph Pillis, director of engineering for industrial refrigeration at Frick, a Waynesboro, Pennsylvania, USA-based unit of Johnson Controls. “And its flexibility allows customization to any plant’s specific refrigeration needs.”

This reduction in refrigerant charge may enhance the safety of food and beverage factory personnel and people living or working in the vicinity of a production plant. In addition, the low charge can in some cases ease the regulatory burden and compliance costs for facilities.

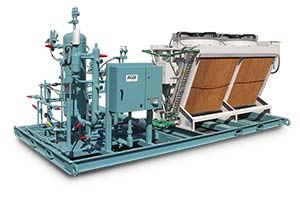

The system’s driving innovation is localized condensing made possible via remote distributed condensing (RDC) units that are managed by Frick’s patent-pending control technology. Instead of feeding centrally condensed liquid ammonia through the system, only ammonia vapor is distributed through the plant. It is then condensed locally, near the evaporators.

The RDC units, which include a condensing heat exchanger (adiabatic, plate and frame, air-cooled or evaporative) and a small liquid supply vessel, are placed near DX evaporators, at the point of liquid use.

The RDC units, which include a condensing heat exchanger (adiabatic, plate and frame, air-cooled or evaporative) and a small liquid supply vessel, are placed near DX evaporators, at the point of liquid use.

As a result of the RDC units, the new system eliminates centralized condensers, the high-pressure receiver and large, long supply and return lines full of pumped liquid.

“Frick’s proprietary, state-of-the-art controls monitor and control liquid levels to make sure we don’t run out of liquid in places where it’s needed,” explained Pillis.

The design of the patented Frick LCCS retains a traditional engine room, which offers the same flexibility, efficiency and familiarity as a traditional liquid recirculation system, but it contains only compressors and a control panel – no liquid ammonia storage vessels. This allows the use of larger, more efficient compressors (up to 25%) than those found in many packaged systems.

Moreover, to date, all low charge solutions have been based on providing rooftop packages, which often require costly alterations to the building structure. With Frick’s LCCS, such accommodations are generally not necessary as the technology can be easily retrofitted to an existing facility. And since compressors are in the engine room and not on the roof, they can be conveniently serviced out of the elements.

Pillis concluded: “Direct and open access to key components makes it easy for inspection, test and maintenance and maximizes worker safety. The modular remote distributed condensing concept enables projects to be scalable based on the application needs.”

About Frick and Johnson Controls

Johnson Controls, a diversified technology company of global scope, manufactures a full line of Frick brand industrial refrigeration equipment for food and beverage production applications. It makes rotary screw compressor packages and packaged equipment with or without variable speed drives. Models are available with capacity control from 100% down to 10% of full load. It also produces condensers, evaporators, AcuAir® hygienic air handlers, vessels, heat exchangers and controls. The company’s state-of-the-art Quantum™ HD control panels lead the industry in performance and reliability. For additional information, visit http://www.johnsoncontrols.com.

Johnson Controls, a diversified technology company of global scope, manufactures a full line of Frick brand industrial refrigeration equipment for food and beverage production applications. It makes rotary screw compressor packages and packaged equipment with or without variable speed drives. Models are available with capacity control from 100% down to 10% of full load. It also produces condensers, evaporators, AcuAir® hygienic air handlers, vessels, heat exchangers and controls. The company’s state-of-the-art Quantum™ HD control panels lead the industry in performance and reliability. For additional information, visit http://www.johnsoncontrols.com.